Ergonomic Scalpel

Industrial Design | DFM | Regulatory | Factory Management | Client Facing

The client came in expressing a need for a more ergonomic, but still disposable scalpel. Seems like something that should already exist, doesn't it?

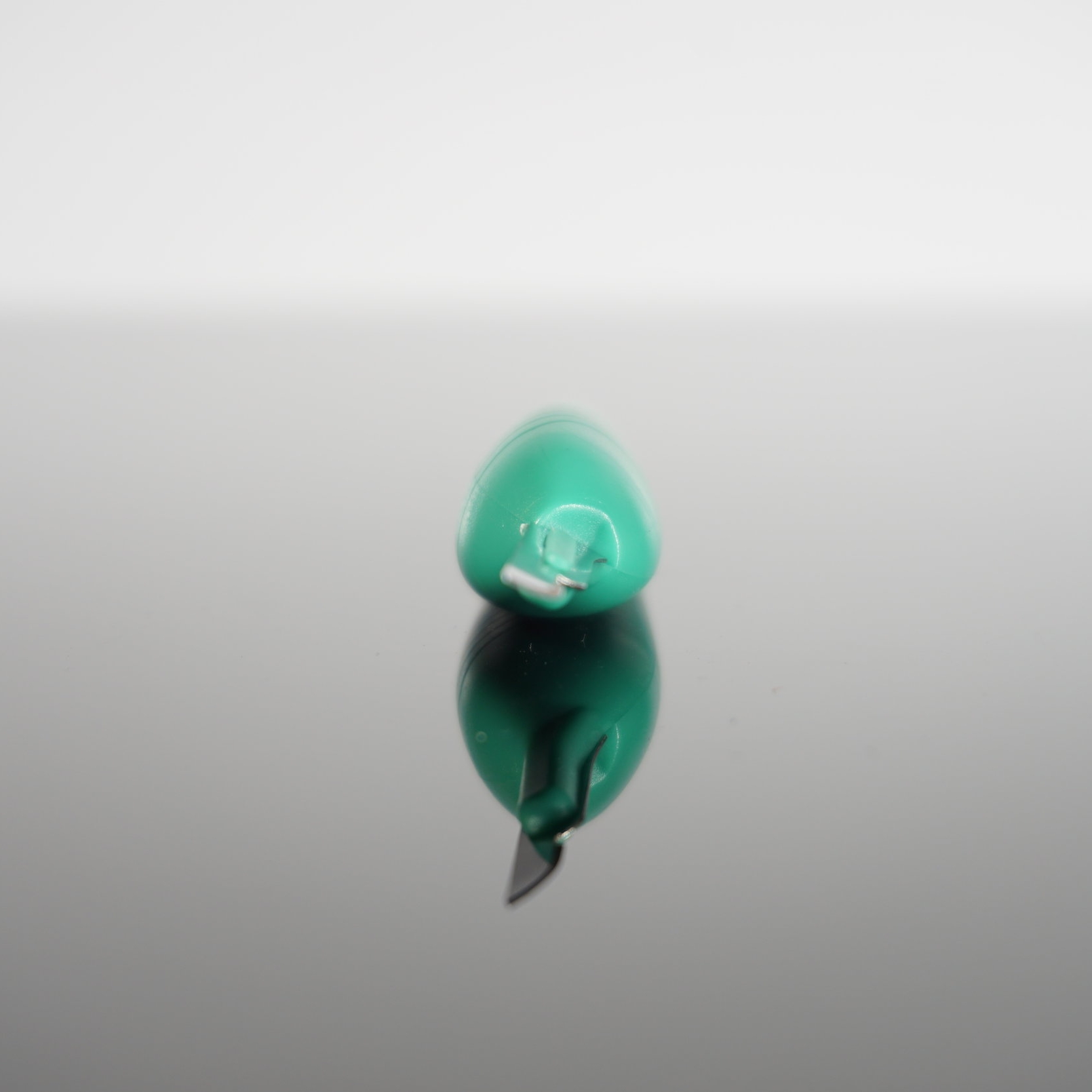

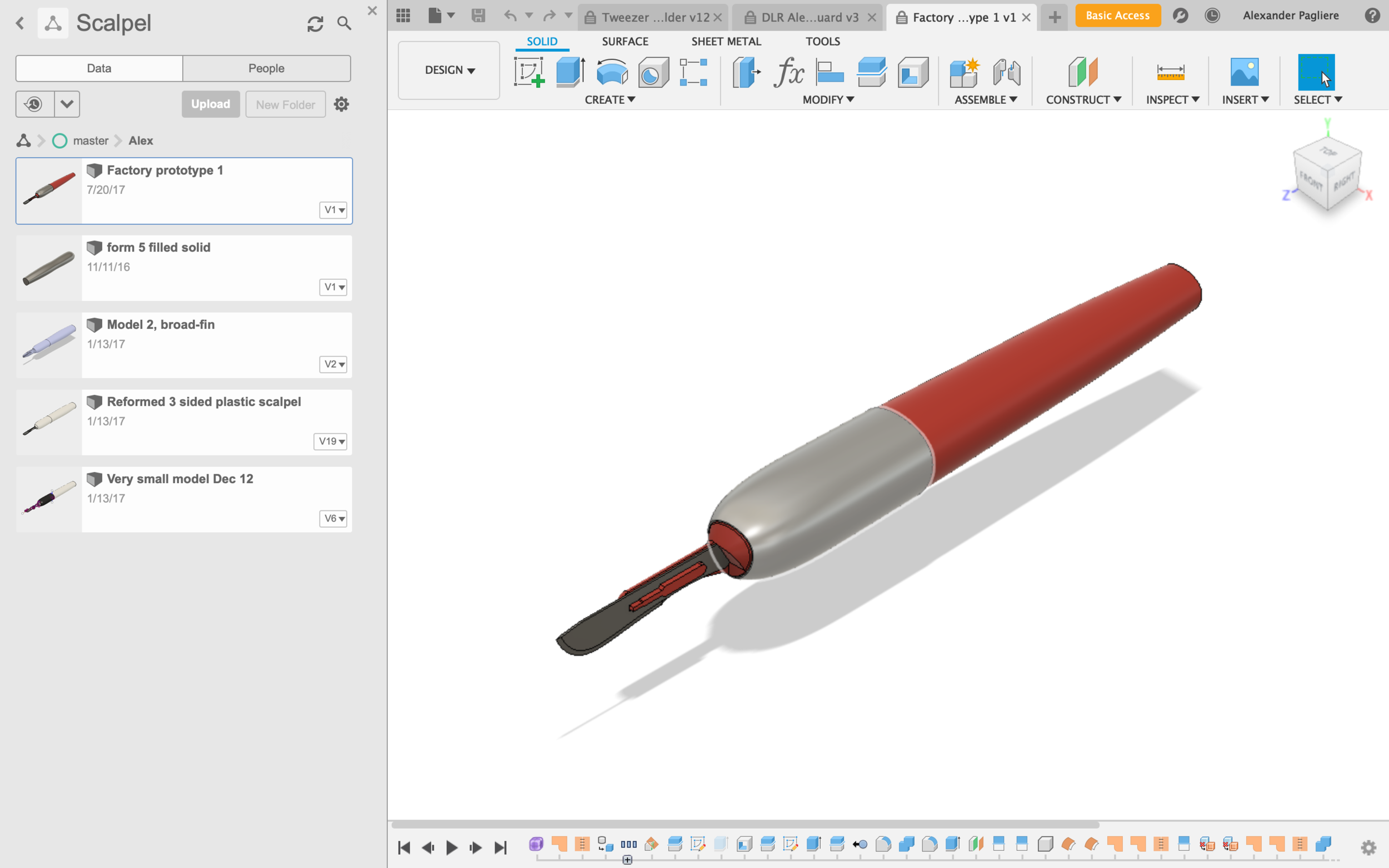

Working with an intern from a local high school, we iterated through shapes, printing each sample on the 3d printer to allow the surgeon to test the comfort of each. Ultimately we found a semi-triangular profile was ideal: the relatively large size is more comfortable for longer surgeries, the light texture gives a better grip, and the broad back surface gives tactile feedback on blade angle.

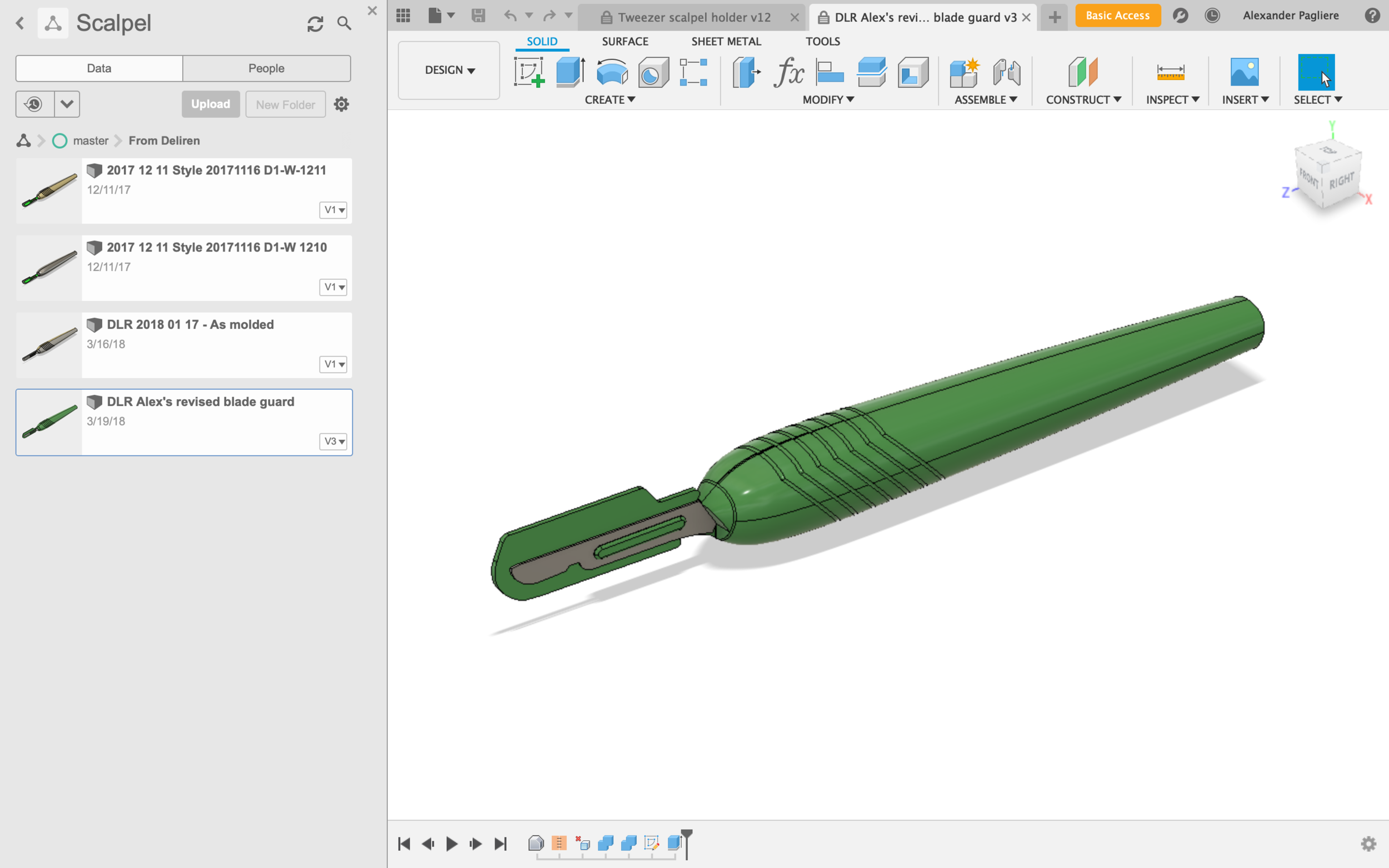

Then I worked with the overseas factory to improve manufacturability, in order to stay cost competitive with the billions-sold generic scalpels on the market while delivering a massive utility advantage.

Finally, we delivered two plastic-injected parts that assemble together, with a heat-stake for blade retention.